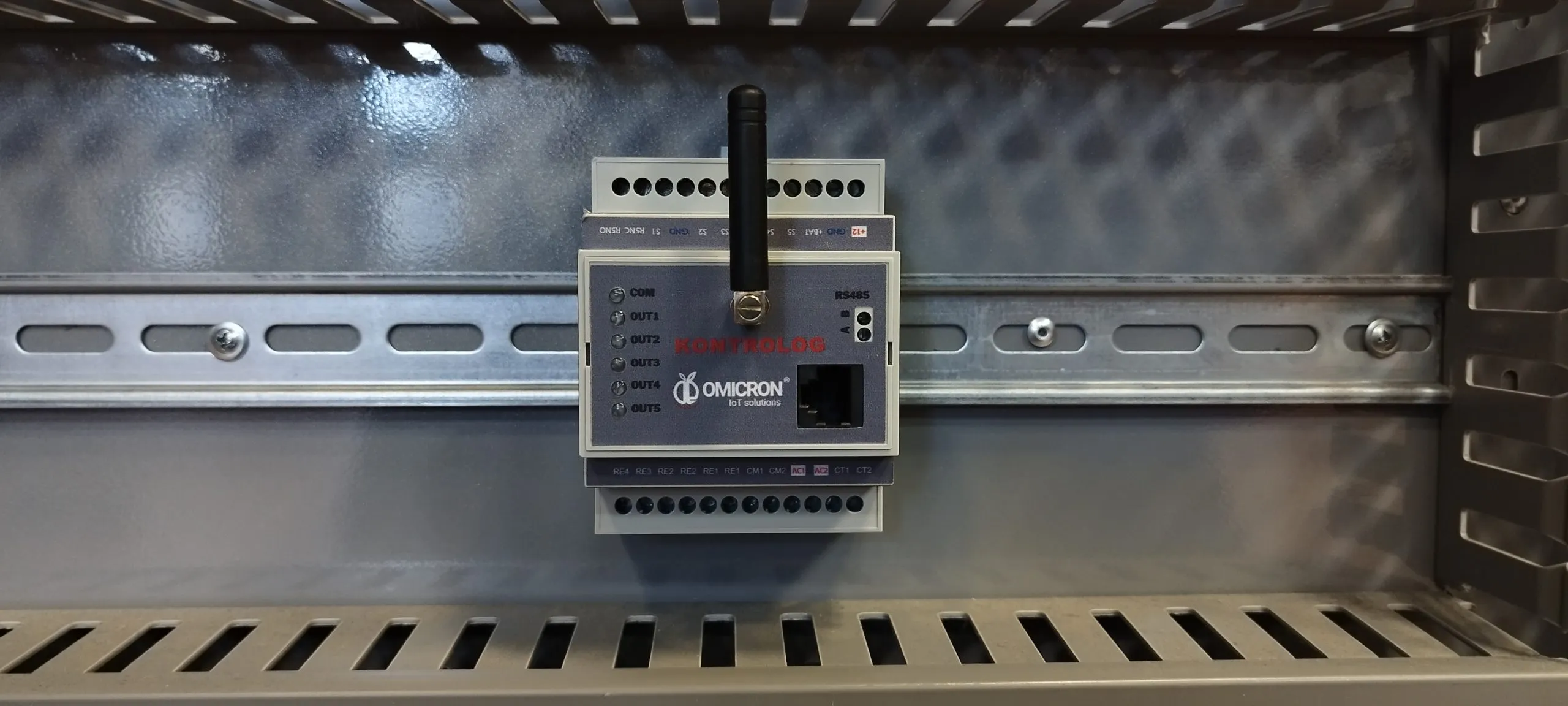

The Kontrolog device is a programmable controller for IoT (Internet of Things), designed for remote and real-time control and monitoring of different processes with high security and precision requirements. Adapted to your application, the device can be easily used after its assembly. It hosts electronic components such as a microcontroller (CPU) and memory, and other hardware elements such as: voltage sources, power outputs, the necessary ports to hold the sensors and the IoT communication module. The microcontroller contains the embedded software, which performs the tasks of: reading the sensors connected to its ports, creating the monitoring packets or frames, configuring and activating the communication module, sending data at intervals that can be variable depending on the programmed publication times, generating alerts and developing control tasks.

It is possible to configure locally or remotely the parameters of each sensor and the device, such as alarm levels and activation time, data publication time, among others. This can be done through the on-site HMI screen, and through a remote configuration platform.

For this purpose, customers are offered an optional license for the use of a remote monitoring and configuration platform for the device, supported by the manufacturer. The use of other user-preferred monitoring and control platforms is also supported.

There are two models of the Kontrolog device, designated by the names Kontrolog 9.3 and Kontrolog 9.2. The main difference between them is that the Kontrolog 9.3 has one output (No. 5) which is analog (4-20mA); while, for the Kontrolog 9.2, all the outputs are relay type.

The main technical characteristics of these two models of the Kontrolog device are listed below.

There is a wide variety of accessories for the Kontrolog that can be ordered, achieving exceptional versatility and ease of use in every case. The careful choice and arrangement of these items allows precise customization of the Kontrolog configuration, adapting it to the specific needs of each user and thus achieving the best possible performance.